Cummins L9 Problems: Complete Guide with 6 Troubleshooting Methods

Many vehicle owners and operators may face Cummins L9 problems. Despite this powerful engine being known for reliability and performance, it can encounter issues affecting efficiency and longevity.

This article will cover common Cummins L9 engine troubleshooting, and how to prevent future problems. So, whether you’re a vehicle owner or a mechanic looking for solutions, keep reading to learn more!

Table of Contents

Cummins Engine: A Comprehensive Overview

Cummins Engine Company is an American multinational corporation that specializes in:

- Designing, manufacturing, and distributing diesel and natural gas engines

- Related technologies such as filtration, fuel systems, and power generation systems

The company was founded in 1919. It is one of the world’s largest engine manufacturers, operating in over 190 countries and territories.

Cummins Services

They offer training programs for technicians and operators, remote monitoring, and diagnostic services to help customers keep their engines running at peak performance.

In addition to its engine manufacturing operations, it also provides a range of support services to its customers, including:

- Maintenance

- Repair

- Overhaul services

- Service call

- Parts and accessories

Who Makes Cummins Engines?

Cummins engines are manufactured by Cummins Inc., a multinational corporation headquartered in Columbus, Indiana, USA. The company has over 60,000 employees worldwide and operates in over 190 countries.

What are Cummins Diesel Engines Used For?

The company’s engines are used in a variety of applications, equipment, and vehicles, including:

- Heavy-duty trucks

- Buses

- Construction Equipment

- Marine vessels

- Mining equipment

They also provide power solutions for data centers, hospitals, and other critical infrastructure.

Why Do Cummins Engines Standout?

Cummins engines and trucks are known for their:

- Durability

- Reliability

- Fuel efficiency

The company’s equipment and vehicle are designed to meet stringent emissions regulations, including those of the Environmental Protection Agency in the European Union and the United States.

They, therefore, invest heavily in research and development to improve their engines’ and trucks’ performance and efficiency while reducing their environmental impact.

Are Cummins Engines Reliable?

They are typically the most dependable motors to power your vehicle or RV. Cummins engines are known for their high torque output, making them popular for heavy-duty applications.

With routine maintenance, diesel engines made by Cummins typically last for millions of mileage. However, the year a unit or motorhome was manufactured will affect your vehicle’s overall reliability.

The Impact of Detention on Cummins Engine Performance

Detention is a term commonly used in the transportation industry to refer to the time a driver waits at a shipper, storage, or receiver’s facility beyond the scheduled appointment time. In recent years, detention has become increasingly prevalent in the trucking industry.

Drivers are reporting longer wait times and more frequent occurrences. Cummins has been particularly affected by detention.

How Detention Reflects on Cummins Engines

Cummins engine problems have been significantly on the rise due to the issue of detention, especially regarding engine performance. When drivers of vehicles are detained for long periods, their engines are often left running. It results in:

- Increased fuel consumption

- Engine wear and tear

- Reduced mileage

- Overall vehicle efficiency

This can lead to costly maintenance and repairs for:

- Engine dealers

- vehicle owners

- Dealerships

- Operators

The Move Cummins Is Making to Counter Detention

Cummins has been partnering with its customers and industry players to address this. They are working to find solutions that reduce detention time and improve engine performance.

Cummins Partnerships

One example is their partnership with the Alliance for Driver Safety and Security, the Trucking Alliance:

- This partnership focuses on advocating for federal regulations.

- They require shippers, owners, and receivers to compensate drivers for detention time.

- In addition to advocating for policy changes, the company is developing new models and technologies.

- They will go to improve engine efficiency and reduce the impact and cost of detention.

Troubleshooting Issues Frequently Encountered by Cummins L9 Engines

No matter how well you maintain mechanical power sources, they will eventually develop problems. They can be anything from minor inconveniences to serious issues requiring immediate attention. Some of them may prevent you from even starting your RV.

You can do troubleshooting by doing the following steps:

- Finding the cause of your engine problem.

- Document these symptoms in detail, including when they occur and under what conditions.

- You can eliminate some of the options by outlining your issue. Understanding the problem area will help you identify the probable diagnosis.

- Use an electronic diagnostic tool to check for error codes for clues to narrow down potential causes.

Cummins L9 problems

You can determine what might be wrong by observing what occurs when you switch on the engine. Here are common Cummins L9 problems that one may encounter with this model:

- The engine Won’t Start

- Rough Idling at Lower RPMs

- Black Smoke

- Lack of Power

- Blue Smoke

- White Smoke.

1. The Engine Won’t Start

One of the most frustrating problems with Cummins diesel engines is when they don’t start or are difficult to start. Here are some common reasons why:

Insufficient Pressure within the Engine

The engine won’t produce sufficient heat to combust the fuel without enough pressure. In general, higher mileage engines are more likely to have this problem. Your Cummins diesel engine can be found to be the problem with a cold engine compression test.

The problem can also be fixed by:

- Replace the worn-out or damaged piston rings.

- Check the cylinder bores to ensure they are free from scoring or scratches.

- Inspect and replace damaged valves.

- Check the cylinder head gasket and replace it if necessary.

- Perform an engine compression test to ensure the pressure has been restored.

Low Diesel Pressure

Fuel supply problems primarily arise due to low pressure.

To determine if this is the issue, the best approach is to:

- Make sure that the tank is adequately fueled.

- Confirming that the engine is receiving fuel from the pump.

- Confirm if the pressure is insufficient.

Slow engine turnover rate

In order for the fuel pump to generate pressure, the engine must rapidly rotate. This pressure triggers the injection process, and without the correct procedures, a Cummins diesel engine may encounter difficulties when starting.

To know if your engine has a slow turnover rate:

- Check the battery’s charge level.

- Check the starter motor for damage or wear.

- Check the wiring connections and clean or tighten.

- Verify the fuel pressure is within the manufacturer’s recommended range.

- Check the coolant temperature, if it’s too low, use a block heater to warm the engine.

- Check the oil level and top it up if necessary.

Insufficient Fuel Inventory

A lack of fuel will result in a difficult start whether there is not enough in the tank or a few supply pipes are broken. A blocked breather may also result in a vacuum that draws fuel back to the supply pipes and tank.

To prevent this:

- Ensure fuel is sufficient in the tank.

- Examine the fuel supply lines and hoses for damage or leaks.

- Check the fuel filter.

- Clean or replace the breather to allow proper ventilation.

- Test the fuel pump’s pressure and replace it if necessary.

Fuel standards

Poor fuel quality has the potential to harm the engine’s internals, particularly the injectors. The failure of the injector itself may result in problems with hard starting.

Ensure that the fuel being used meets the recommended fuel standards.

2. Rough Idling at Lower RPMs

If your Cummins L9 engine runs rough at a lower RPM, it could indicate underlying issues. Here are some common reasons why:

Malfunctioning Fuel Injectors

Cummins diesel fuel injectors’ damaged parts will lead to:

- Reverse flow

- Decrease in fuel pressure

- Delay in injection

This causes jerky running or a complete failure to ignite.

For it to work:

- Replace the worn-out parts.

- A thorough inspection is to ensure no additional problems.

- A test drive to ensure the engine is running smoothly.

Reduced Fuel Pressure

An often-mentioned catalyst for problems with engine starting and running is fuel pressure.

It can be most effectively ruled out by:

- Ensuring the fuel tank is filled sufficiently.

- Monitoring the fuel delivery from the pump.

- Check the actual pressure with diagnostics.

Limited Air Supply to Engine

There may be a restricted intake if the engine isn’t getting enough air. The most typical limitations are:

- Unclean air purifiers.

- Clogged pipes.

- Malfunctioning butterfly valves.

- Faulty air flow sensor on the intake.

To clear restrictions:

- Clean or replace the air cleaner to ensure that air is flowing freely to the engine.

- Clear or replace any blocked pipes to restore proper airflow.

- Check the butterfly valves in the intake and make sure they are functioning properly.

- Use an electronic diagnostic tool to check the airflow sensor and replace it if necessary.

Insufficient supply of fuel

To function properly, the engine requires an adequate reserve of fuel.

This can easily be fixed by:

- Check for damage to supply pipes.

- Inspect and clean the fuel tank breather and the turbo filters for obstructions.

Quality of Fuel

To operate properly, inner Cummins diesel engine elements require high fuel quality. Poor fuel quality can harm Cummins diesel injectors and make other parts of the engine run poorly.

Here are some solutions to help you achieve this:

- Purchase fuel from a reputable source that meets the required standards for fuel purity.

- Install a fuel filter to remove contaminants and protect the engine’s internal components from damage.

- Add fuel additives to help maintain fuel quality and prevent injector clogging.

- Monitor fuel storage conditions.

- Regularly inspect the system components for signs of corrosion, leaks, or damage.

3. Black Smoke Emission in Engines

If your Cummins L9 engine emits black smoke, it can indicate various underlying issues. Black smoke means you should inspect the fuel and air systems. Here are some common reasons why:

Malfunctioning Fuel Injectors

When fuel injectors malfunction, they may supply too much fuel to the engine, resulting in excessive smoke. Worn-out or clogged injectors can cause this.

You can deal with this problem by:

- Doing a thorough inspection.

- Cleaning or replacement of the injectors is necessary.

Issues with Faulty Fuel Injection Pump

If the injector pump is not functioning correctly, it can cause fuel to be delivered to the vehicle or engine unevenly or excessively, leading to black smoke.

The pump may need to be repaired or replaced.

Clogged Air Filter

A clogged or dirty air cleaner can restrict airflow to the engine. It causes incomplete combustion of the fuel, leading to black smoke.

A regular air cleaner maintenance schedule can help prevent or fix this issue

Defective Intercooler or Turbocharger

If the intercooler or turbocharger is not functioning properly, it can produce black smoke due to reduced engine efficiency.

A visual inspection or diagnostic test can identify the problem.

Cylinder Head issues and blocked Valves

Cylinder head problems such as worn seals or clogged valves can cause incomplete fuel combustion, leading to smoke.

A valve clearance check or cylinder head inspection may be necessary to address this issue.

4. White Smoke Emissions

White smoke from a Cummins L9 engine exhaust can indicate several issues, such as:

Timing belt/chain failure

If the engine and pump timing are out of sync, it can cause incomplete combustion and produce white smoke from the exhaust. It can be due to the following:

- A faulty injector pump

- A worn timing belt

- Internal engine problems on your vehicle

A timing test can help diagnose this issue.

Weak engine compression

If the engine compression is low, it can cause incomplete combustion and produce white smoke from the exhaust. Worn piston rings, damaged cylinders, or other internal engine problems can cause this.

If you face this problem:

- Conduct a compression test to determine the cause of the weak engine compression.

- Replace damaged parts.

- Conduct regular maintenance.

- Avoid over-revving the engine.

Oil or water in the Fuel

If there is water or oil in the fuel, it can result in incomplete combustion and white smoke from the exhaust. Water can get into the fuel system through condensation or a leaky seal. Oil can enter the system through a faulty injector or internal engine trouble.

Inspecting the fuel system and testing the injectors can pinpoint this problem. You can do this by:

- Drain the fuel tank.

- Inspect and remove any traces of water or oil.

- Test the injectors to identify any faulty ones.

5. Decreased Power Output

Your Cummins diesel engine is lacking power if it has trouble igniting or accelerating. You can connect these problems to be fuel-related if you experience Cummins engine problems.

Ensure you check the following:

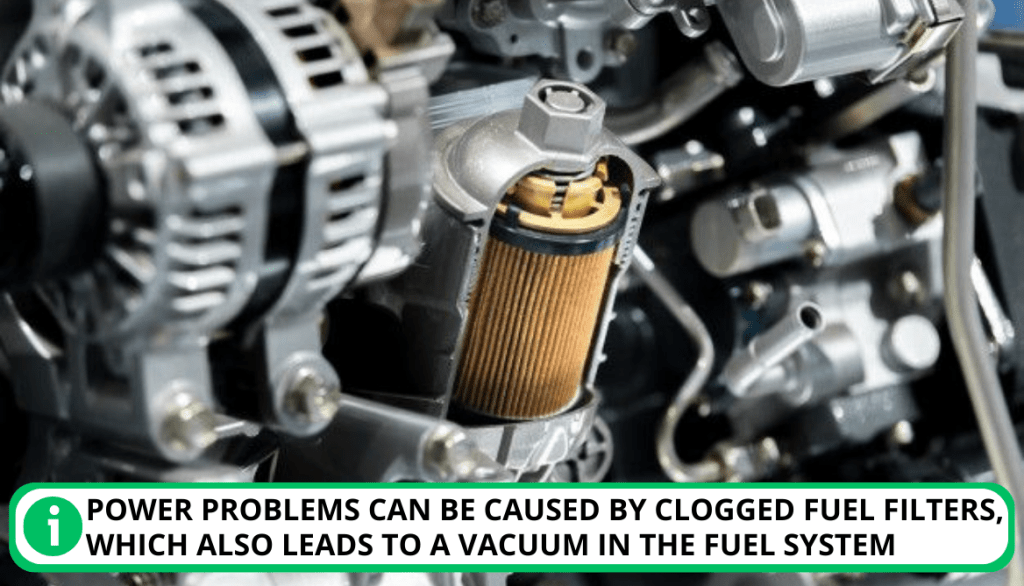

Clogged Fuel Filters

Power problems can be brought on by dirty fuel filters, which can also result in a vacuum in the fuel supply. Also, dirt molecules & carbon get picked up in the oil & are captured in the filters.

If the power issue persists, you might have to replace them.

Slack accelerator connection

The throttle cable must maintain the proper tension for the engine to run correctly on your vehicle. The cause of insufficient power might be a loose connection.

Limited Airflow

True power from a Cummins diesel engine can be limited by an obstruction in the air intake system. Restrictions include pipe blockages and a filthy air cleaner.

To fix obstruction:

- Check the air intake ducts and pipes.

- Clean the air intake system.

Faulty injection system

Defective Cummins injectors can lead to:

- Reverse flow

- Decrease in fuel pressure

- Ignition problems

Similar to other components in this, damaged supply pumps, pipes, control sensors, and pressure can all have a negative impact on power.

If fuel is the issue, you might need to replace any worn-out or damaged parts by installing new one’s parts.

6. Emissions of Blue Smoke

Your diesel engine is burning oil in addition to diesel if you see smoke that has a blue tint. The causes of blue smoke from your Cummins diesel engine include the following:

Engine wear and tear

Seals may become damaged or develop cracks due to wear that happens naturally over time. This may result in blue smoke from the oil burning and leaking.

Faulty valve or Stem Seals

In this case, the piston rings and cylinder piston rings both wear out, but the engine oil leak comes from a different place. Check all the following to diagnose where the engine oil leaks properly:

- Valves

- Pistons

- Seals

- Cylinders

Replace or tighten any leaking parts.

Over-lubrication

If the vehicle or engine oil reservoir is too full, the oil will burn alongside the fuel, resulting in blue smoke.

You might need to remove some engine oil or vehicle storage.

Faulty fuel pump

If the lift pumps and injectors in your RV are faulty, diesel fuel will be contaminated with oil from the turbo engine and tank. Blue smoke is produced as a result of the turbo and engine igniting this mixture.

You might need to replace the pumps.

Troubleshooting Cummins diesel engines necessitates a thorough understanding of how they work and how to recognize warning signs. A professional diagnosis is the ideal bet for a reliable and precise result.

You should make a thorough care schedule before you have to go through the stressful process of diagnosing no-starts in your engine.

Cummins Engine Care Tips

One way to avoid having to fix Cummins’s diesel engine problems is to maintain your equipment properly.

Preventative Measurements

As a preventative measure, it centers on the following:

- Cleaning up your diesel engine.

- Repair or replacing worn-out parts and other internal components.

Preventative Maintenance

Preventative maintenance prolongs the life of your diesel engine and is less expensive than fixing problems after they arise.

- Creating a scheduled timeline is the most effective method to keep track of when your car needs to be serviced and what needs to be replaced or upgraded.

- Keep track of short-term and long-term care objectives on a check sheet or calendar.

- Sort them according to how often you should be carrying them out.

We advise segmenting your schedule into the following categories.

Everyday

Ensure you carry out routine inspections daily on the following:

- Coolant: Inspect the level of the coolant and replace it as necessary.

- Water separation between the reservoir and the fuel filters: Inspect and drain the fuel filters.

- Oil: Verify the amount of engine and gear oil and make any adjustments necessary

- Filter: Make sure the filter tank is clean.

Every 3 Months

After three months, do the following inspections:

- Repeat: Carry out everyday checks.

- Pump belt: Examine and adjust the pump belt as necessary.

- Electric: Inspect each electrical link to make sure it is safe.

- Air purifier: Look for any blockages and clean them properly.

- Zinc anodes: Evaluate the zinc anodes and change them as necessary.

Every 6 Months

Establish a regular 6 months schedule by:

- Repeat: Carry out the daily and the three months checks first.

- Replace the: filters and engine oil, the fuel filter mounted on the engine, and the water and fuel separator component.

- Antifreeze: Examine the concentration of antifreeze as a percentage and make any necessary corrections.

- Impeller and pump: Check the water pump and impeller for wear.

Annually

Each year, conduct the following checks:

- Repeat: Carry out the daily, three, and six months checks first.

- Check the: Pumps, EGR cooler, batteries, and engines’ mounting bolts, air purifier element, vibration isolators. Make sure repairs or replacements are done where necessary.

- Belts: Check the belt tensioner; fix or replace them if need be.

- Flush: Assess the fuel systems, and drain the fluids from the heat exchanger, gear oil cooler, and aftercooler.

You can extend the life of your Cummins diesel engine and keep it running with a full warranty and a low risk of experiencing any issues if you use this comprehensive checklist of when and what your mechanic needs to check.

Cummins ISL9 Reviews

Cummins ISL9 is a reliable and well-regarded engine in the market. Several reviewers have lauded the engine’s design.

Some provided statistics to prove it to be one of the most reliable and best-designed engines available. A veteran mechanic reported that the ISL9 had been one of the finest engines on a vehicle while working throughout his 25-year career.

Many reviewers claim it is the best diesel engine since its introduction about 17 years ago. However, some owners have reported issues with the engine, which are not widespread. Despite this, most reviews are positive, with high praise for this engine.

FAQ

Is the Cummins L9 a good motor?

Yes, the Cummins L9 is a good motor. It is known for its reliability and durability.

What is the life expectancy of a Cummins L9?

The life expectancy of a unit of a Cummins L9 engine is around 500,000 to 1,000,000 miles, depending on mileage, care, and usage.

What is the difference between Cummins L9 and L9N?

The Cummins L9N is a newer version of the Cummins L9 engine. It is designed to meet the latest vehicle emissions standards and features an advanced after-treatment system.

How many Litres is a Cummins L9?

The Cummins L9 engine is a 9-liter turbo-four engine.

Conclusion

In conclusion, the Cummins L9 engine is reliable and durable. Like any engine, it can experience problems if not properly maintained. The most common Cummins L9 problems include starting problems, running rough at a lower RPM, black, blue, or white smoke, and lack of power.

Routine maintenance is crucial for the smooth functioning of the engine. It is essential to follow the recommended schedule and perform regular checks. If you experience any trouble with the engine, you should consult a qualified mechanic.

What is the most crucial maintenance tip for the Cummins L9 engine? Comment below and include common problems you have faced.

I`m a current Law Enforcement Officer working within the Counterterrorism Bureau in New York State. I have been Camping for over 20 years. My styles of camping include tent, car, truck, van, and RV travel trailer. I have a YouTube channel where I teach all types of camping with an entertaining method: https://youtube.com/@TheSmallsRVAdventures