Freightliner M2 Bulkhead Module Problems: Troubleshooting and Wiring Diagram

Encountering Freightliner M2 bulkhead module problems can be a real challenge. Resolving these issues is not an easy task and may often lead to stressful situations. However, in case you are unfamiliar with this module and need a clear understanding, I have got you covered.

Read this detailed guide to learn about the location of this module, five associated problems with solutions, and a step-by-step guide to program this module and reset errors. With that, let’s start exploring right away!

Table of Contents

A Closer Look at the Freightliner M2 Bulkhead Module

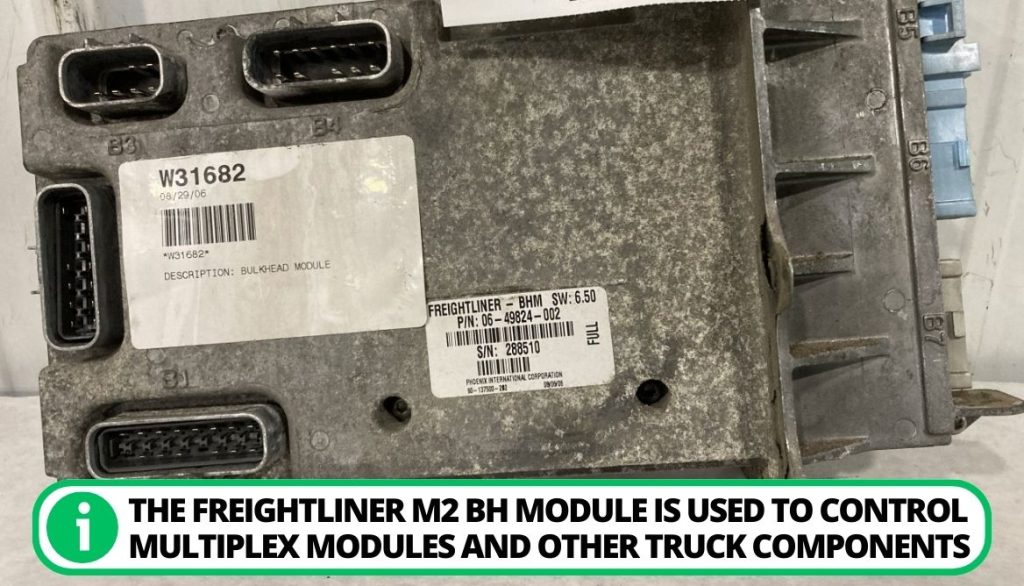

The Freightliner M2 BH module, often referred to as the BHM, serves to manage your truck’s multiplex modules and various other vital components. To execute this task effectively, the bulkhead module relies on a system of harness connections. On the engine side, the bulkhead module features four essential connections. These include:

- Forward chassis harness;

- An engine harness;

- Two harnesses are designated for the front wall of the vehicle.

Furthermore, on the cab side, you’ll find three key harness connections, each of them dedicated to managing the dash harness. However, it is important to note that only Freightliner models manufactured from 2016 onwards are equipped with bulkhead modules.

These modern models operate at a 500k auto baud rate, and if the need arises to replace them, it’s necessary to ensure that the replacement module also adheres to specific auto baud rate requirements.

Where Can You Spot the Freightliner M2 Bulkhead Module?

If you are searching for the bulkhead module in a Freightliner, it’s located on the cab side of the vehicle. To pinpoint its exact location, focus your attention on the front wall on the engine side.

To guide you further, if you can see the steering column, simply direct your gaze slightly downward, and there you will find the bulkhead control module you are looking for.

Freightliner M2 Bulkhead Module Problems and Solutions Table

After having a brief intro about what Freightliner M2 BHM is and where it is located, now I will enlight you about the most frequent problems faced by drivers along with the solutions. Firstly, have a quick look at the issues in the form of a table before discussing them in detail in the later part:

Challenge | Solution |

Misfiring Harnesses: | Inspect and replace faulty harnesses which can cost over $150 including labor |

Datalink Issues: | Reprogram the BHM or replace it, with an approximate cost of $150-$200 |

Shorted Wire (J1939 and J1708 Codes): | Repair shorted wires that are causing fault codes |

BHM Awake Mode Issues: | Verify the ignition switch position and replace a faulty switch |

Numerous Output Issues: | Consider replacing the BHM for efficient operation costing at least $2000 |

Addressing Freightliner M2 BHM Problems: 5 Solutions

Freightliner M2 stands as a symbol of reliability and performance. However, like any complex machinery, these trucks are not safe from technical issues. Let’s explore its problems in detail:

Problem 1: Misfiring Wiring

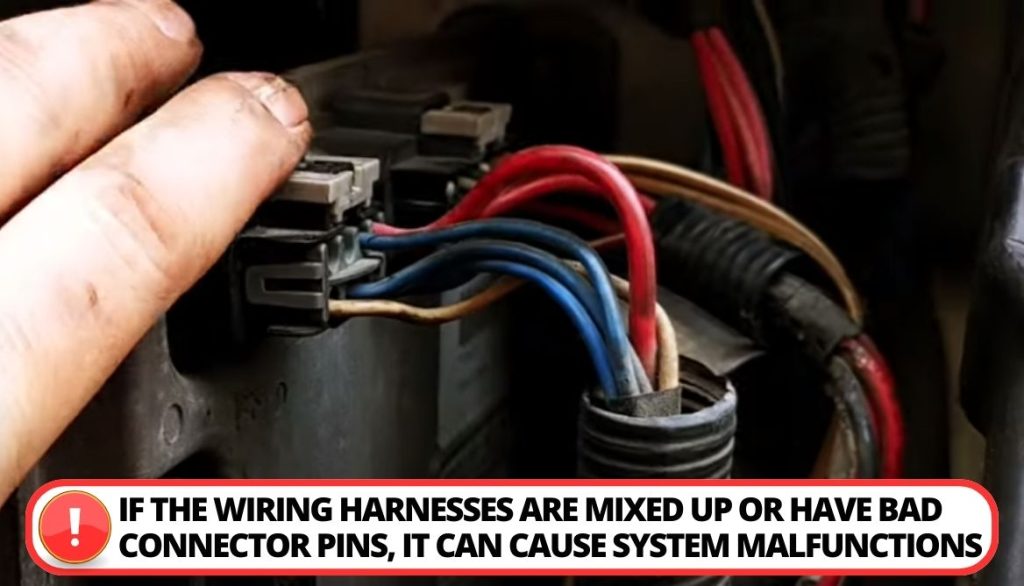

The Freightliner M2 relies on a harness connection to control different electrical systems within your truck. If these harnesses misfire or have poor connector pins, it can lead to system malfunctions and generate confusing faulty codes. This can not only affect the vehicle’s performance but also cause confusion for the driver about the internal condition of the truck.

To resolve misfiring harnesses, inspect the connections carefully.

- If you identify a faulty harness, it’s essential to replace it. This replacement process often involves expert inspection and labor costs, which can add up to over $150.

- Harness damage can result from factors like dirt, corrosion, or power spikes, so regular maintenance and inspections such as checking all the fuses can help dismiss the issue.

- Also, do not forget to check engine light and the air pressure on a regular basis if your truck stays steady.

Problem 2: Frequent Data Link Issues

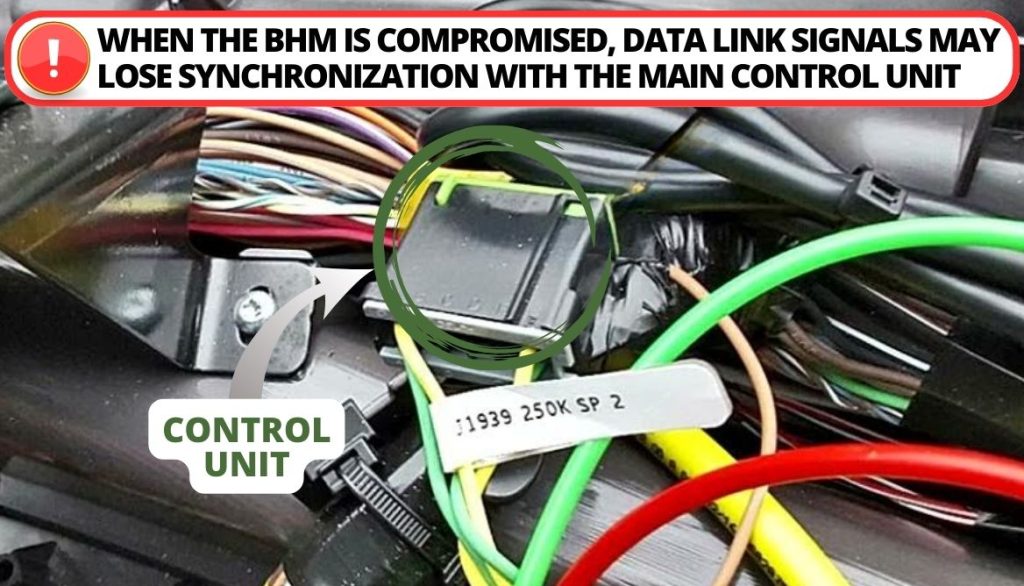

Datalinks in your truck connect various components, switches, and sensors, allowing for rapid data transfers and enabling individual components to report issues to the central computer system. When the BHM is compromised, data link signals may lose synchronization with the main control unit.

Regular maintenance and inspections of your datalinks can help prevent issues and ensure effective communication between vehicle components.

Problem 3: J1939 and J1708 Error Codes from Short Circuits

The J1939 and J1708 codes are datalinks used by the BHM to report faults within the truck’s system. If you experience difficulty to find these codes, the most probable diagnosis is a shorted wire. This issue can prevent proper communication between components and the central computer system.

Regular inspections can help prevent these shorted wire issues and maintain smooth communication within the vehicle’s electrical system.

Problem 4: BHM Wake-Up Mode Issues

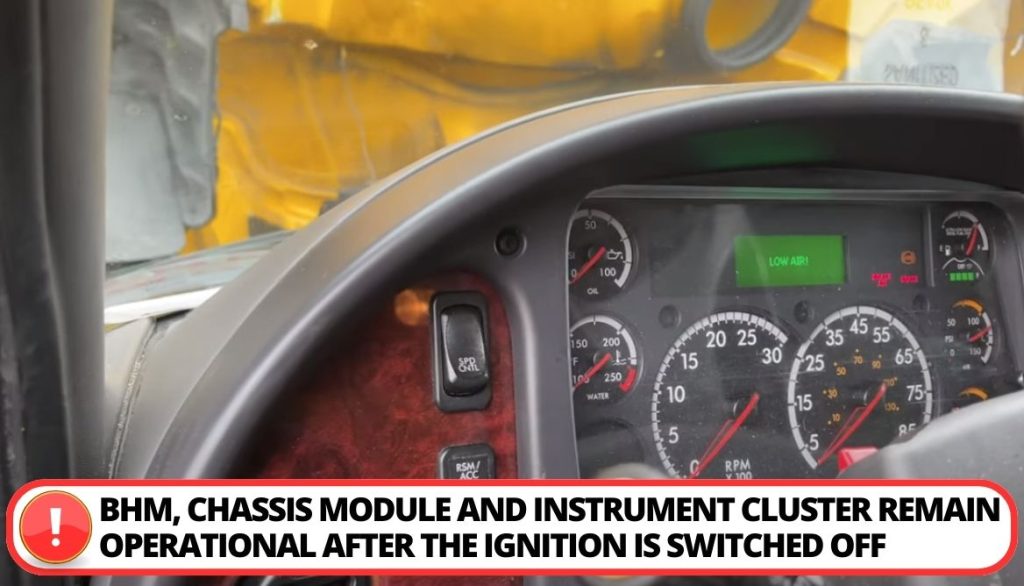

Occasionally, the BHM, Chassis Module, and Instrumentation Control Unit remain awake even after turning off the ignition. This can result in the vehicle losing valuable battery power distribution modules, which is often inconvenient and frustrating for the driver.

Problem 5: Various Output Problems

The BHM plays an important role in analyzing driver inputs and controlling various components in your truck, such as:

- A/C Clutch;

- Test Light;

- Horn.

When the BHM malfunctions, it can lead to multiple systems failing simultaneously, resulting in a loss of functionality and performance.

How to Interpret Freightliner M2 BH Module Codes?

When dealing with the Freightliner M2 BHM, you’ll encounter two types of faulty codes: the J1587 and J1939 fault codes. These codes provide valuable insights into the health and performance of your truck’s electronic control units (ECUs). I will explore these codes in detail below to help have a better understanding.

Understanding J1587 Fault Codes

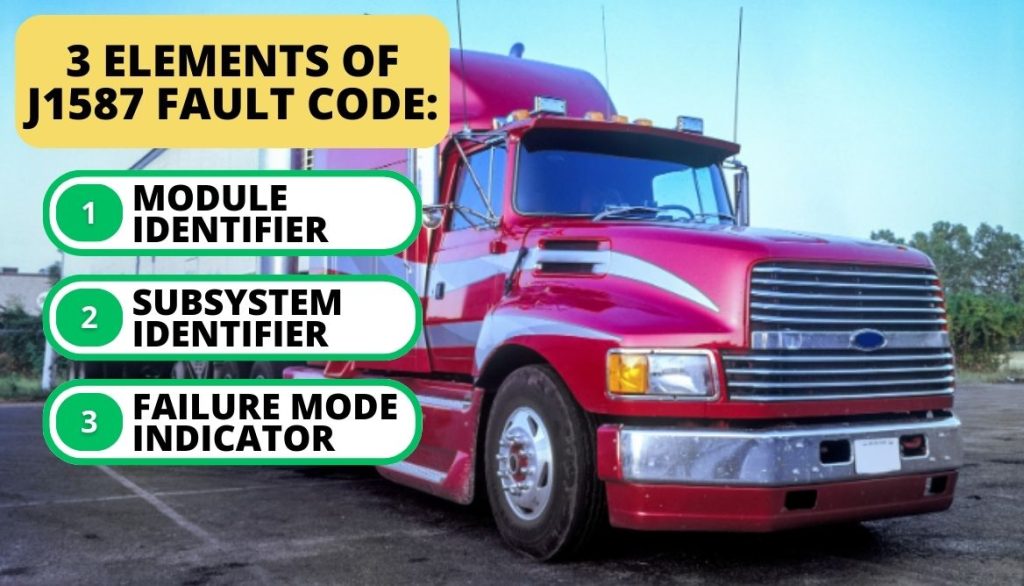

J1587 fault codes are composed of three key elements, each serving a specific purpose:

- Module Identifier: MID is the source identifier of the electronic control unit (ECU) responsible for the fault. It tells you where the issue originates within the truck’s systems.

- Subsystem Identifier: SID highlights a specific subsystem or function within the ECU that is experiencing a problem. It narrows down the scope of the issue.

- Failure Mode Indicator: FMI informs you about the nature of the function failure. This element indicates the nature of the fault, providing valuable information for troubleshooting and repairs.

Understanding J1939 Fault Codes

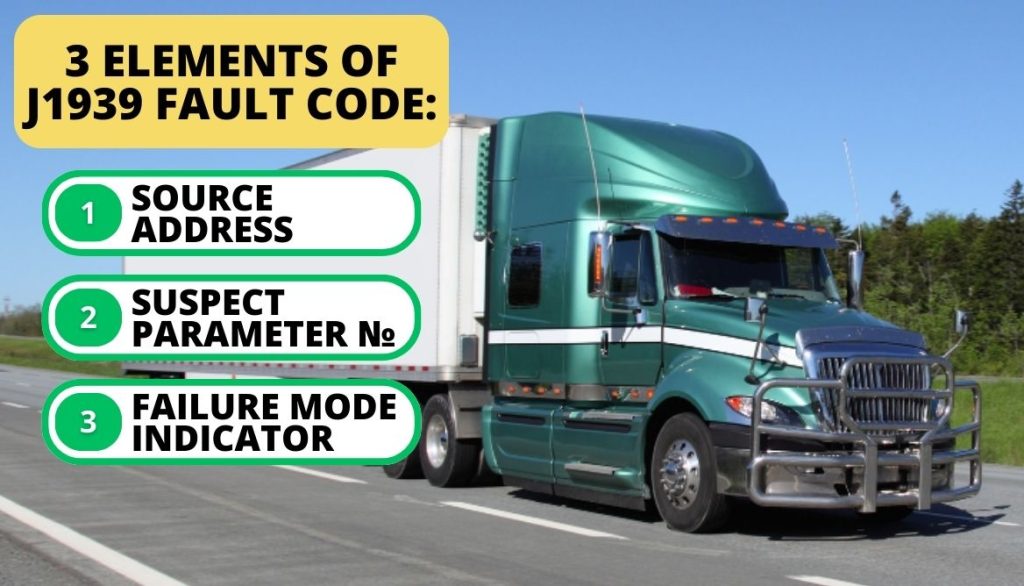

Similar to J1587, J1939 fault codes also comprise three critical components:

- Source Address: SA identifies the source of the electronic control unit (ECU) fault. This element pinpoints the specific ECU that’s encountering the problem.

- Suspect Parameter Number: SPN signifies a particular parameter or function within the ECU that is experiencing a failure. It helps isolate the exact area of concern.

- Failure Mode Indicator: Just like in J1587 codes, FMI in J1939 codes indicates the type of function failure. It provides details on the nature of the fault, aiding in effective troubleshooting.

Navigating the Freightliner M2 Bulkhead Module Wiring Diagram

Now, I will outline three essential wiring diagrams for the Freightliner M2 module. These diagrams play key role in understanding the entire network of wiring and connections within the module. Thus, providing valuable insights into its operation and facilitating effective troubleshooting and maintenance.

Diagram 1. Location of the Main PDM

Let’s check out the first main PDM diagram:

- Bulkhead Module,

- Main PDM Fuse Box.

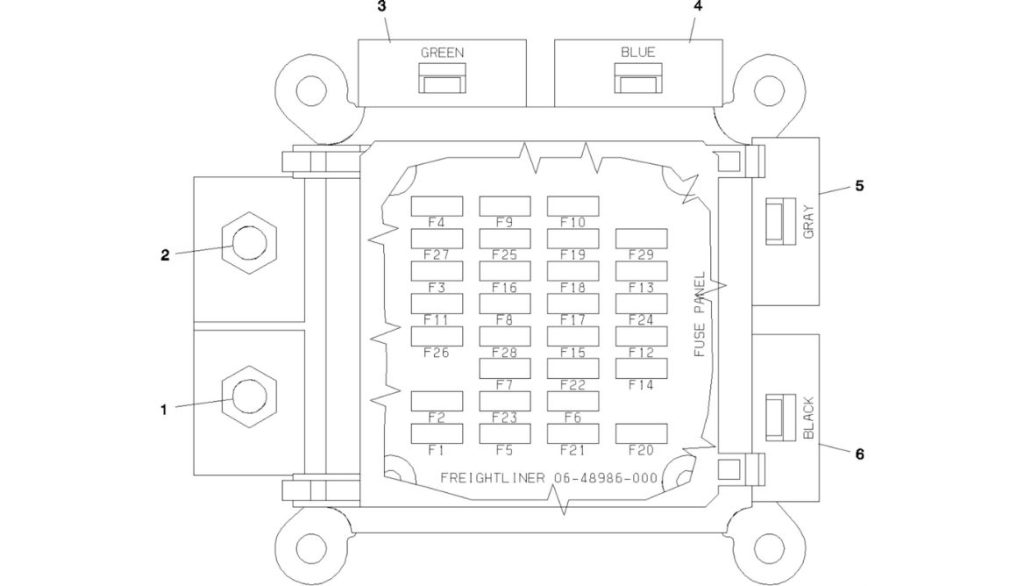

Diagram 2. Main PDM Fuse Box

The second diagram highlights the following:

- Battery Power Mega Fuse 1;

- Battery Power Mega Fuse 2;

- Engine Harness (Green);

- Forward Chassis Harness (Blue);

- Forward Chassis Harness (Gray);

- Frontwall Harness (Black).

Diagram 3. Cab PDM

Lastly, explore the Cab part in detail:

7 Easy to Program a Freightliner Bulkhead Module

Listed below are the easy seven steps to program the bulkhead module. Let’s check them out:

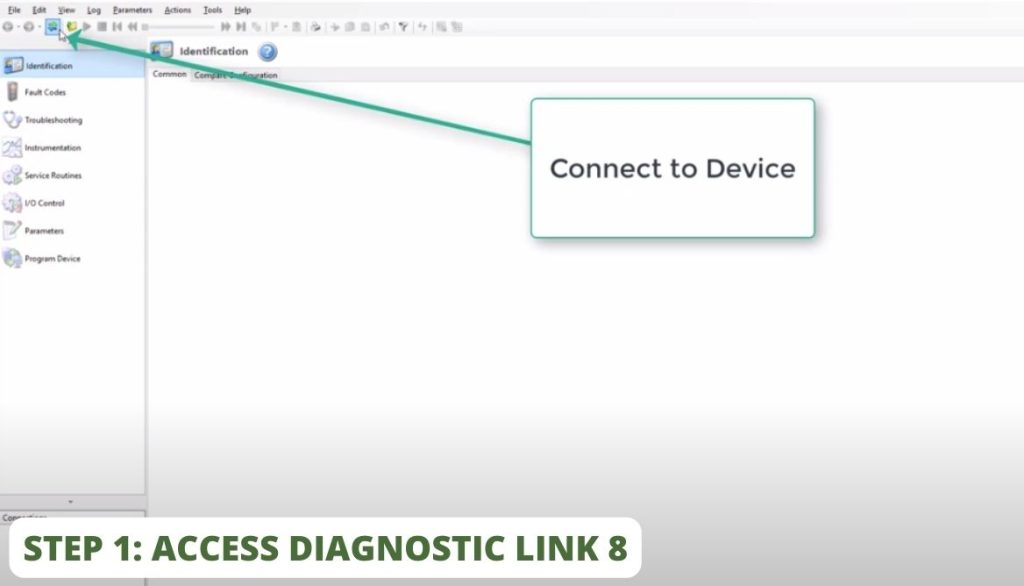

Step 1: Access Diagnostic Link 8

Initiate the process by connecting the drive and opening the diagnostic computer Link 8. Once you are in, click on the “Standard” tab to access the BHM data. Here, you can review the current configuration of your BHM.

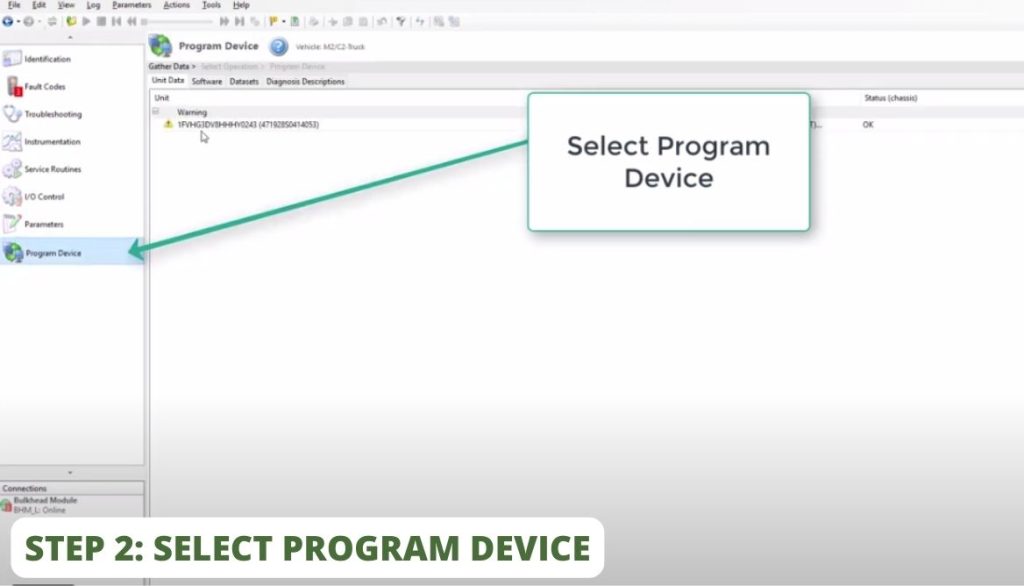

Step 2: Select Program Device

Now you have to select the program device.

- On the left side menu, choose “Program Device.” Ignore any warning codes you may encounter at this point.

- Next, Hover over the right side and click on “Remove All” to clear the existing data.

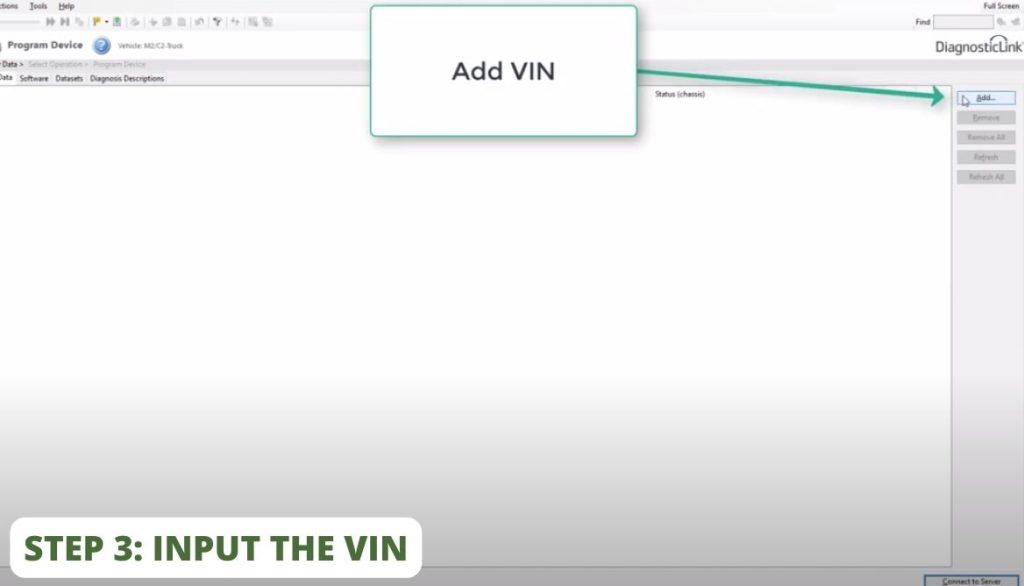

Step 3: Input the VIN

Once the warnings are cleared, click “Add” to input the Vehicle Identification Number of your Freightliner M2. Confirm the input by clicking “OK.” A code will appear on the screen, indicating that a request has been made and a connection to the server is required.

Step 4: Connect to Server

Now, let’s move on to connecting to server:

- Click on “Connect Server,” located on the right corner of the screen. When the connection is successful, you’ll see a “Status: OK” notification.

- Afterward, hit the “Next” button, which can be found just below the “Connect Server” button.

- Following this, press “Connect,” to confirm the connection.

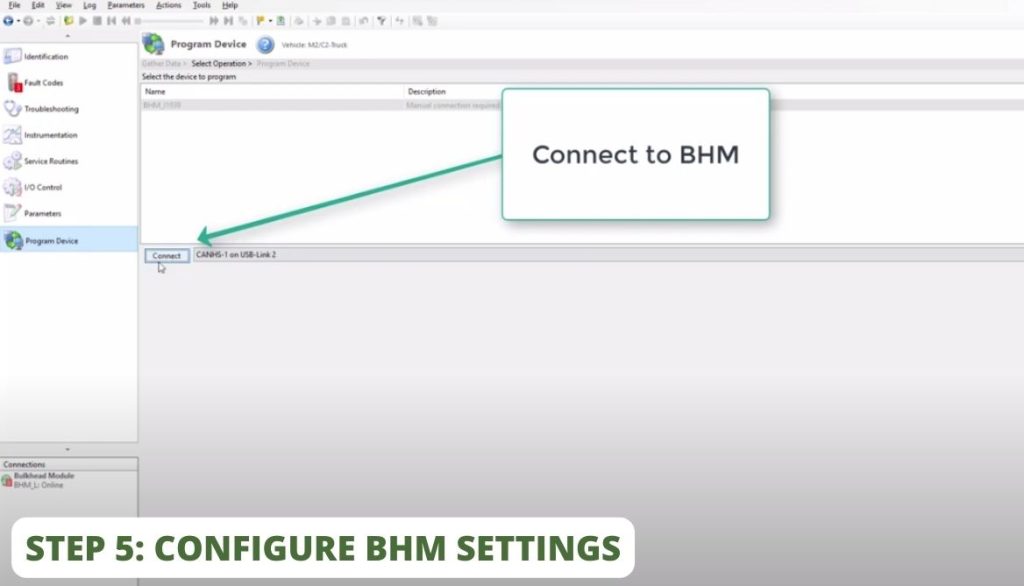

Step 5: Configure BHM Settings

The next part is to tweak BHM:

- You will also see your VIN listed. Select it, and then click on the most recent settings that appear.

- Click “Next.” A prompt will appear to verify the BHM data.

- Click “Start” to begin the programming of the BHM software.

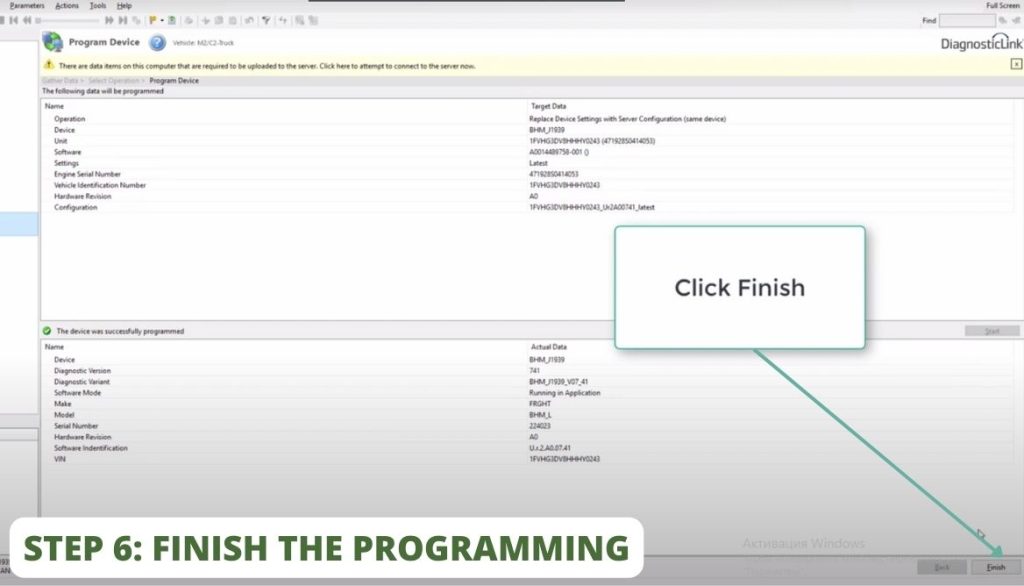

Step 6: Finish the Programming

Once the programming is done, click “Finish.” A new symbol or code will appear, indicating that a connection to the server is still needed to upload data. This information will be displayed in the status section.

Here, tap “Connect to Server” again, and patiently wait for the connection to be established. Once it’s completed, you will see that the BHM is connected.

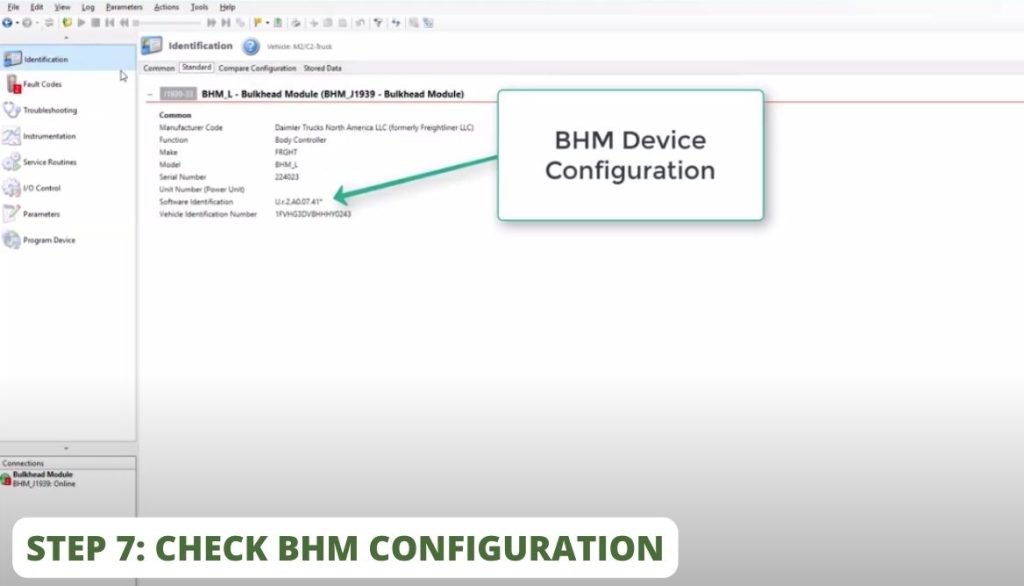

Step 7: Check BHM Configuration

The last part is to check the configuration:

- On the left menu tabs, click on “Identification.” This will allow you to review the BHM device configuration.

- Hover over the left bottom of the screen, right-click on the “Bulkhead Module,” and select “Close Connections.” Then, right-click again and choose “Clear All Connection Errors.”

How Can You Safeguard Your Freightliner M2 Against BMH Issues?

Preventing costly BHM replacements is a smart way to keep your Freightliner M2 in optimal condition. These modules are often durable, and with some straightforward maintenance practices, you can extend their lifespan. I have discussed below on how to acheive this:

- Periodically check the condition of your BHM to identify early signs of wear or damage.

- Corrosion can lead to faulty connections, causing power spikes that may harm your BHM. Promptly address corroded wires and connections.

- After extended highway trips, make it a habit to clean your vehicle’s internal components and check air pressure. Dirt and debris buildup can significantly affect the module health.

- As soon as you identify malfunctioning wiring harness, replace them promptly. Timely replacement helps prevent issues and ensures proper functioning.

FAQ

Can I continue driving my Freightliner with a faulty M2 BHM?

You can not drive a Freightliner M2 with faulty BHM. It could lead to safety and operational issues, so it’s best to address and repair the problem before continuing to drive.

How much does it cost to replace the BHM?

The cost to replace a Freightliner M2 BHM can vary significantly depending on factors like the specific model, location, and whether it’s a new or used part. On average, you can expect to pay $500 to $2000 for the replacement, including parts and labor.

What are the symptoms of a bad Freightliner M2 bulkhead modules?

A faulty Freightliner M2 BHM can exhibit various symptoms, including electrical Issues, warning tail lights, communication errors, unresponsive controls, loss of data, starting problems, and overheating.

Do All Freightliners have BHM?

Not all Freightliner trucks have a BHM. It varies depending on the specific model, configuration, and year of manufacture. The BHM is typically found in medium and heavy-duty Freightliner M2 series, where it plays key role in managing various body and chassis-related functions.

What is a faulty control module?

A faulty control module refers to an electronic component within a vehicle that has malfunctioned. Control modules are responsible for managing and regulating various systems in modern vehicles, such as engine, transmission, anti-lock parking brake, airbags, lighting circuits, and running lights.

Conclusion

The final say is that Freightliner M2 bulkhead module problems can be solved with a proper guide. In case you face overheating, slave modules, electrical, and output issues with the A/C clutch, testing lights, and horn, count them as symptoms and it might be time for BHM replacement.

Moreover, if the issue is with fault codes, you may need to repair the shorted wire to resolve the issue. Have you ever faced the need to replace the BHM module and what were the symptoms behind it? Share your experience with me in the comment section below.

I`m a current Law Enforcement Officer working within the Counterterrorism Bureau in New York State. I have been Camping for over 20 years. My styles of camping include tent, car, truck, van, and RV travel trailer. I have a YouTube channel where I teach all types of camping with an entertaining method: https://youtube.com/@TheSmallsRVAdventures