6.7 Cummins Belt Diagram: Don’t Ignore These 3 Warning Signs About

The 6.7 engine by Cummins is a powerful and widely-used diesel engine known for its durability and performance. Understanding the 6.7 Cummins belt diagram is essential for properly routing the belt. The engine’s serpentine belt is critical in powering various engine accessories.

This article will provide a serpentine belt overview, Freightliner, Cummins ISB diagrams, and 7 efficient steps to change the belt smoothly. So, keep all the hassle at bay, and follow this guide until the end.

Let’s dive in!

Table of Contents

An Insight Into The Serpentine Belt

The serpentine belt is a highly important part of the 6.7 Cummins and is responsible for powering various systems such as:

- The power steering

- Water pump

- Air Conditioning systems

- Alternator through several pulleys

Its name derives from its serpent-like winding around the engine.

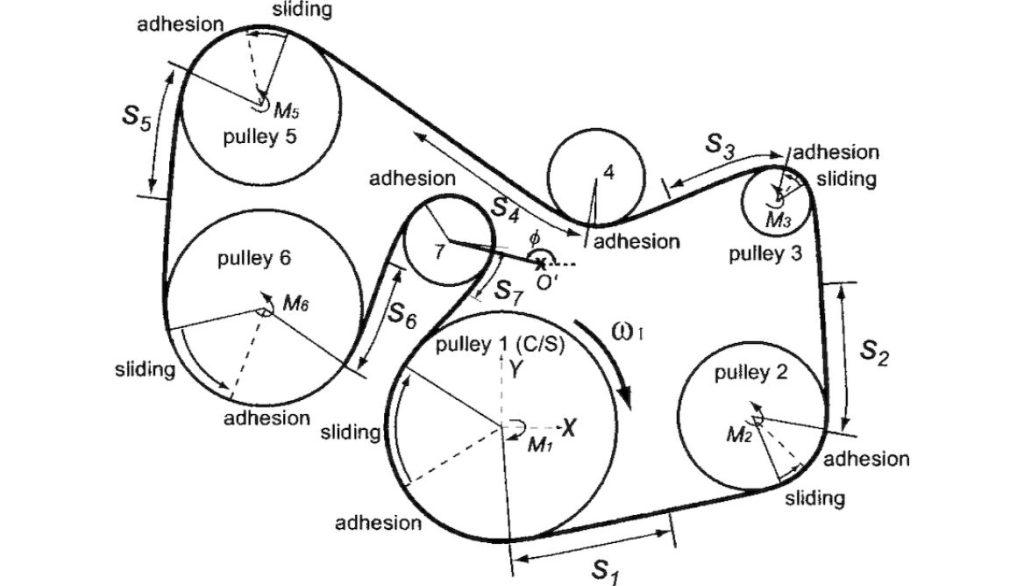

Cummins ISB 6.7 Serpentine Belt Routing Numbered Diagram

The routing in the above diagram goes like the following:

- Idler pulley

- Accessory belt drive

- Power steering pulley

- Radiator fan pulley

- Crankshaft pulley

- Air conditioning compressor and water pump pulley

- Accessory belt drive tensioner

- Generator

To avoid the belt starts again, you can use the diagram above as a guide when changing the serpentine belt. Once you think the belt is in the correct position, ensure that it’s properly aligned by double-checking. Securely fasten the serpentine belt without any sagging or movement.

After ensuring the routing is correct, tighten the belt carefully, and avoid exerting an extra force that can cause it to break and necessitate the process of the belt starts again.

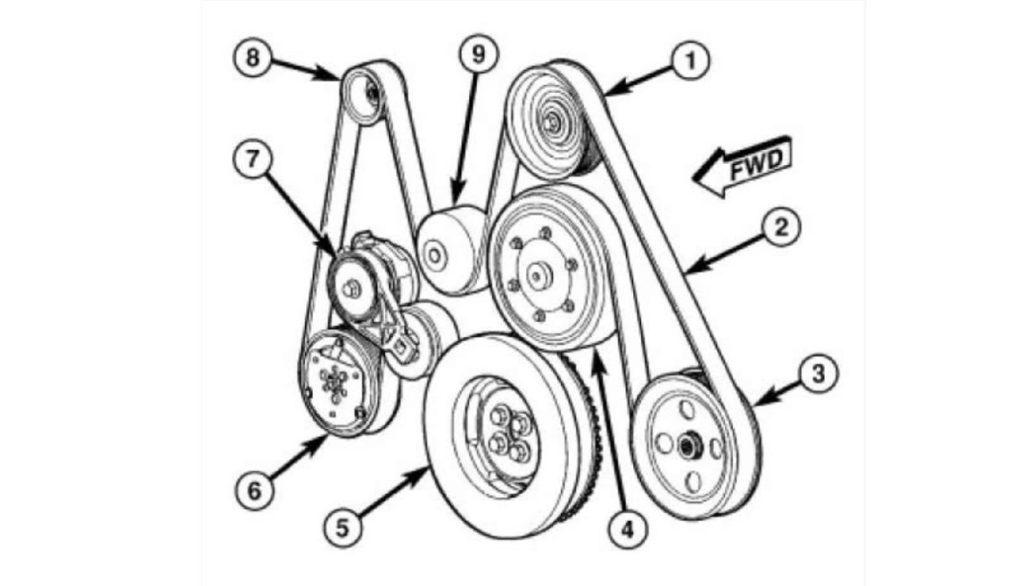

Freightliner Cummins 6.7 Belt Diagram

The simplicity of the belt routing diagram makes it easy to understand, allowing for a quick and effortless replacement of the accessory belt. Succeeding the diagram’s instructions, you can complete the task in a few minutes. However, knowing that the bolt needs to be loosened to release the belt tensioner is essential.

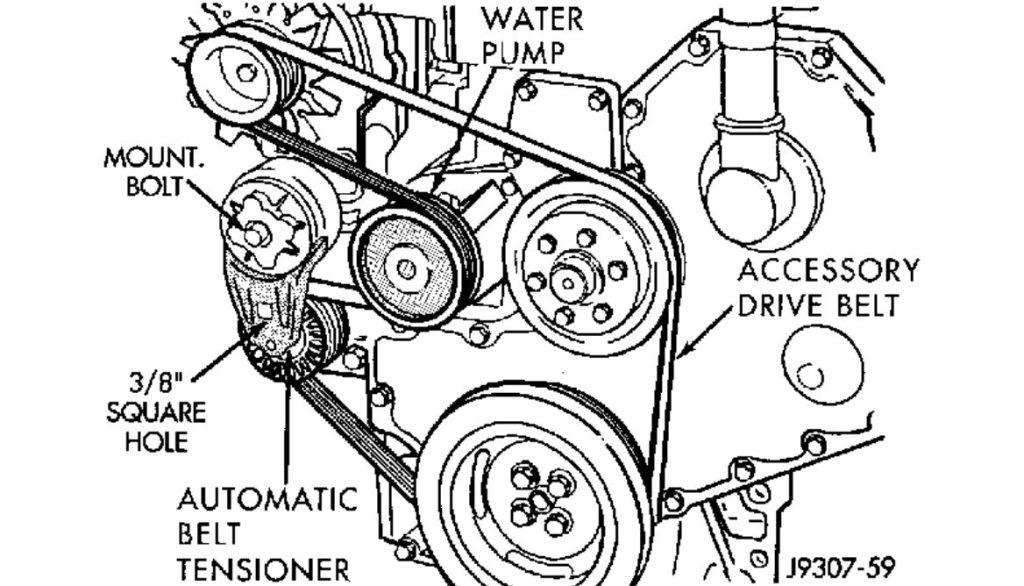

Cummins ISB 6.7 Belt Tensioner – Engine and Warranty Guide

Here is a quick insight into Belt Tensioner:

- This engine component functions automatically and is responsible for maintaining proper belt tension.

- Positioned in the center of the engine’s external front, it is secured by only a few bolts.

- While part number 3104029 is required, several others may also be suitable, with at least four identified. This number is essential when searching for a replacement at an auto or RV parts store.

Warranty Period Length

The dealer will determine the warranty length, usually six months and a year. Although Cummins’s production of this component has been outsourced to China, it will be manufactured to precise specifications.

Fortunately, you can easily find a local parts supplier by conducting an online belt tensioner search.

Repairing 6.7 Cummins Belt Effectively

Recognizing when to adjust or tighten a serpentine belt is easy if you pay attention to the warning signs that the belt emits. A chirping or screaming noise is a telltale sign of a failing belt.

Measures to Avoid the Belt Failure

Take the following measures to avoid old or new belt failure:

- Regularly maintain your vehicle

- Use a high-quality serpentine belt

- Make sure that belt tension is set correctly

- Check for any misalignment in pulleys

- Avoid Overloading

- Monitor serpentine belt performance timely

Note: By following these measures, you can reduce the risk of belt failure in your RVs hot engine and ensure that your vehicle stays running smoothly for years to come.

Look Out for a Replacement

The 6.7 belt for Cummins is no longer designed for larger vehicles, so it may be more expensive than other belts due to shortage. However, obtaining a replacement belt should be easy. You can find the replacement belts at the following places:

- Auto parts stores

- Online marketplaces (like Amazon)

- Salvage yards

- Cummins dealerships

Note: It is important to replace old or worn-out belts to prevent potential engine damage or failure. New, high-quality belts are recommended for optimal engine performance and safety.

Belt Problems Associated with the 6.7 Serpentine Cummins

Over the years, various design upgrades have been made to the Cummins components, including the serpentine belt. Implementing modern materials has resulted in improved functionality and durability of the product.

See this video to inspect your Cummins belt more effectively.

However, the belt remains made of a flexible material that experiences considerable uneven wear and tear as it rotates at a high RPM during every drive. Check a few of the necessary things below:

Symptoms to Take into Account

The serpentine belt in a 6.7 Cummins engine is responsible for driving several engine components, including the alternator, power steering pump, and air conditioning compressor. If the belt is in need of attention, you may notice some of the following indications:

- Squealing or chirping noise

- Belt slippage

- Reduced power steering assist

- Battery warning light

- Overheating

These all suggest that the belt needs to be replaced.

Component Failure

In some cases, issues with the serpentine belt may be responsible for the failure of other components rather than the components themselves.

- Worn serpentine belts, in particular, cause power steering and air conditioning systems to malfunction.

- If there is a power steering failure or a decrease in air conditioning performance, it is advisable to inspect the belt first.

- Faulty belts can cause problems with the performance or failure of these parts.

Breakdown of Belt

If the serpentine belt breaks, it can cause several subsystems to fail, and your truck may become inoperable. In such a situation, you can either seek roadside assistance or replace the belt if you have a spare belt.

If there are belt problems with the serpentine, the check engine light will illuminate, and the tuner may display a Diagnostic Trouble Code (DTC) error message if the belt is the source of the issue.

Mileage Count for Spare Serpentine Belt

Here are the details you should know:

- Modern serpentine belts have a lifespan of 50,000 to 100,000 miles.

- However, inspecting the belt periodically after the first 50,000 miles is important to ensure it’s not wearing out prematurely.

During these inspections, you can also check engine light and the belt tensioner.

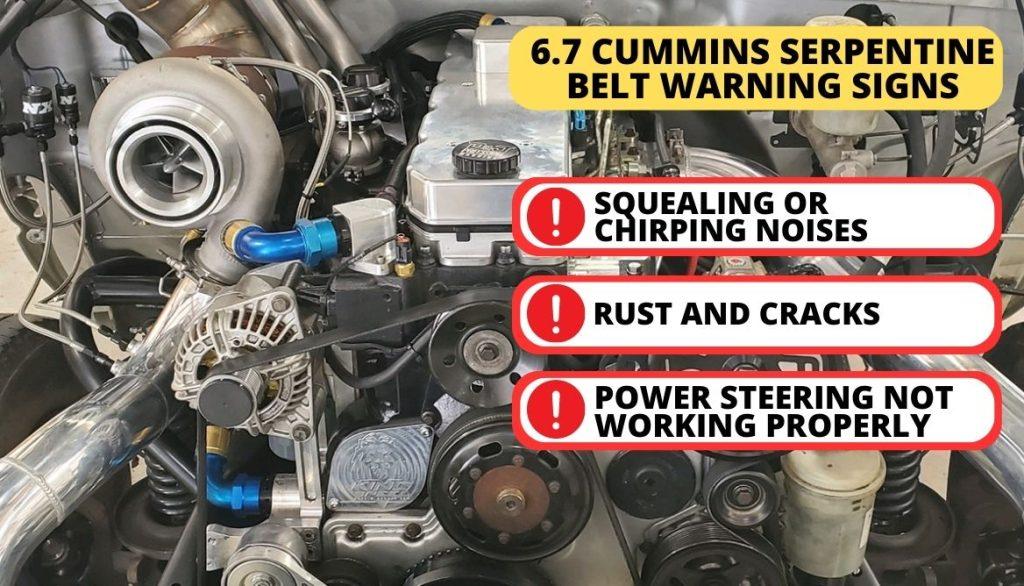

6.7 Cummins Serpentine Belt Warning Signs

Introducing more advanced materials in the market can increase the efficiency of serpentine belts and lead to longer-lasting manufacturing.

However, despite advancements in materials, serpentine belts remain pliable and subject to high-speed rotation while driving or idling. Hence, it’s common for belt problems to arise due to uneven wear and tear. Below are a few of the most common issues:

Squealing or Chirping Noises Coming from the Belt

Serpentine belts may produce squeaking and chirping noises when they begin to slip, and several factors can contribute to slippages, such as:

- Insufficient belt tension

- Loosening of the belt

- Foreign material on the belt

- Restrictions on the clockwise rotation of belt and crankshaft pulley

It’s best to examine your car and identify any potential issues carefully.

Rust and Cracks Visibility on the Belt

It’s essential to inspect your serpentine belt regularly for signs of wear and tear, including:

- Missing pieces

- Cracks

- Broken or split ribs

- Uneven wear

These indicators suggest that the serpentine belt has deteriorated, and it is time to replace it.

Power Steering or Air Conditioning Not Working Properly

When the power steering or air box stops working, checking the serpentine belt before inspecting any other part or spare belt is important. A damaged or broken serpentine belt can cause many problems, including these subsystems failing to operate correctly.

Therefore, ensuring the serpentine belt is in a good condition is crucial to prevent such issues.

Tips to Change the Serpentine Belt on 6.7 Cummins

Replacing the serpentine belt for the first time can be a challenging task. But, by following the instructions below, you can change the belt effectively by yourself:

- Open the hood of your car.

- Remove the tensioner from the AC pulley.

- Remove the old belt by rotating the tensioner counterclockwise (undo one bolt).

- Succeeding the instructions carefully, you can go ahead and install the new belt according to the serpentine belt schematic.

- You can adjust the tensioner after installing the new belt.

- Reinstall the bolt and turn the tensioner counterclockwise once the belt has passed over it.

- Double-check engine light and the tension by starting the engine, reopening the hood, and closing the airbox.

See this video for a much better understanding.

Our Verdict

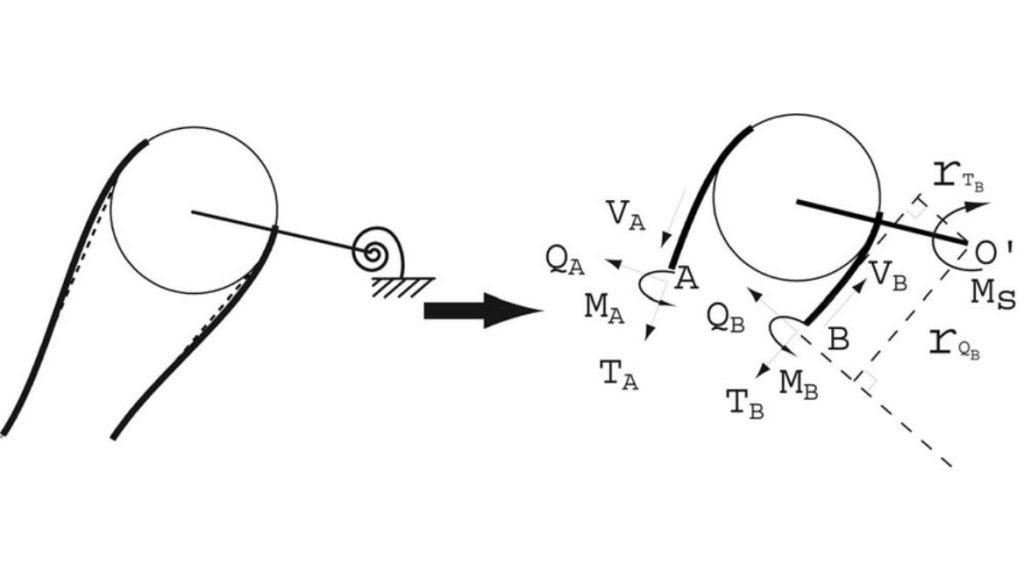

A clear understanding of how the serpentine belt must be routed around a crankshaft pulley is crucial for the engine’s proper functioning. The belt plays a large role in powering essential components, and any mistakes in its routing can cause the belt to slip or break, leading to the failure of these components and possible engine damage.

- To ensure that the belt is routed correctly, it is advisable to refer to a serpentine belt diagram.

- The diagram provides a detailed illustration of the ideal belt path around each pulley, making it easy to identify any routing errors.

- Installing the belt incorrectly can lead to costly engine damage, and therefore, the serpentine belt diagram is the best tool to prevent such mistakes.

FAQ

How much boost can a stock 6.7 Cummins handle?

The stock Cummins 6.7, in its most extreme state, the original equipment manufacturer (OEM) fuel system of the 6.7L Cummins (including the lift water pump, CP3, and injectors) is capable of supporting up to 530 rear wheel horsepower (RWHP).

How much HP can a 6.7 Cummins handle?

The Cummins 6.7, with its remarkable ability to handle up to 400 horsepower and 1,000 pound-feet of clean diesel torque, this powerhouse engine sets a new standard for performance.

What is Cummins’s biggest engine?

Cummins’s biggest and largest engine is the 4,000HP QSK95.

How many cylinders is a Cummins 6.7?

The cylinders in Cummins 6.7 are 6. The 2021 edition of the 6.7L Cummins Turbo Diesel offers even greater horsepower and torque, while also preserving the engine’s legendary durability and efficiency that are typical of diesel engines.

Is a 6.7 Cummins a 24-valve?

Yes! A 6.7 Cummins does have a 24-valve. The 6.7L Cummins engine that was installed in Dodge trucks between the model years 2013 to 2018 is a 24-valve engine with common rail fuel injection and is commonly referred to as the CR 24-Valve Cummins.

What size turbo is on a 6.7 Cummins?

6.7-litre Cummins engines feature a 60mm turbo.

Conclusion

Substituting the 6.7 Cummins serpentine belt is a simple task involving engine components. After loosening one bolt, the belt can be removed by simply pulling it. Then, the old belt can be replaced with the new belt, ensuring that it is correctly routed.

Have you ever replaced a serpentine belt by yourself ever before and did you find the 6.7 Cummins Belt Diagram helpful? Let us know what you think about this in the comment section below. Your feedback is valuable!

I`m a current Law Enforcement Officer working within the Counterterrorism Bureau in New York State. I have been Camping for over 20 years. My styles of camping include tent, car, truck, van, and RV travel trailer. I have a YouTube channel where I teach all types of camping with an entertaining method: https://youtube.com/@TheSmallsRVAdventures